- The Ops Digest

- Posts

- 🔥 The Silent Profit Killer: Inter-Branch Chaos

🔥 The Silent Profit Killer: Inter-Branch Chaos

How AI stops your warehouses from robbing each other blind

Welcome to The Ops Digest!

AI-powered order management is flipping the script in manufacturing and distribution. Each week, we drop no-BS insights to slash wasted costs, tighten workflows, and automate the grunt work.

👉BTW: There’s a copy/paste AI prompt below that can surface $200K+ in hidden transfer waste TODAY.

Let’s roll.

🚨 Your Branches Are Playing Hot Potato with Inventory

And it's costing you a fortune.

Picture this trainwreck:

Chicago needs 500 units. Cleveland has them collecting dust.

Chicago panic-orders from supplier: $800 in expedited freight.

Cleveland? Ships that same SKU to Detroit… who doesn’t need it.

Detroit sends it back next week. Three trucks. Zero revenue.

Sound familiar?

If you’ve got 3+ branches, chances are you’re torching $200K a year in bad transfers, rush freight, and duplicate safety stock.

Fact: Multi-location distributors overspend 40% on logistics compared to peers (Manhattan Associates). Why? Because one branch never knows what the others actually have.

⚡️ AI-Powered Order Management That Pays for Itself

Manual entry isn’t just boring, it’s expensive. Every typo, billing correction, and delay chips away at margins. Meanwhile, account managers are stuck in copy-paste purgatory instead of closing deals.

30-second order processing (straight from email/PDF to ERP)

99.9% error-free accuracy

$260K+ annual savings proven by leading distributors

Go live in 30 days with zero training or workflow change

👉 One team keeps burning $6–10 per manual order and losing 125+ hours a month. The other automates the grind, saves six figures, and scales without burnout.

See how in 100 seconds.

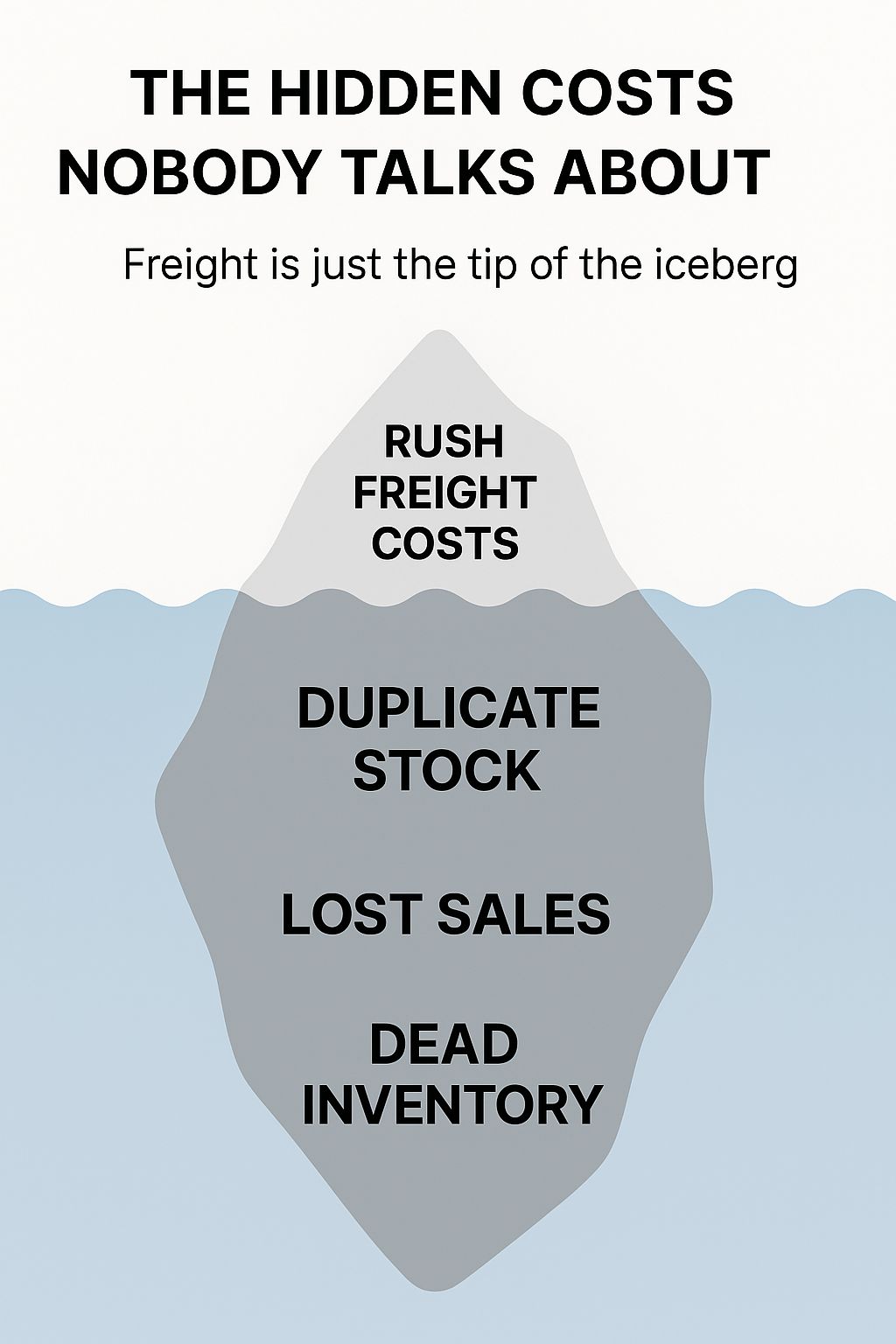

💰 The Hidden Costs Nobody Talks About

It’s not just freight. It’s everything:

Double buying: Two branches order the same dead SKU

Ping-pong transfers: Product boomerangs across states chasing phantom demand

Customer churn: "Sorry, out of stock" while 500 units rot 50 miles away

Rush orders: Paying premium fees because you didn’t know Toledo was swimming in stock

Dead money: Hoarded “just in case” inventory tying up capital

One electrical distributor found $1.2M in duplicate SKUs across just 4 branches. Four warehouses, the same dusty parts, multiplying like rabbits.

💡 Your AI Branch Coordinator (Spin It Up This Weekend)

AI can run interference. But it needs the right ammo.

Step 1: Pull Your Data (30 min)

What to export from your ERP/WMS:

TRANSFER HISTORY (Last 30-90 days):

Date, From_Location, To_Location, SKU, Quantity, Cost, Type(Regular/Emergency)

CURRENT INVENTORY BY LOCATION:

Location, SKU, Current_Qty, Avg_Daily_Usage, Days_Supply

RECENT SALES BY LOCATION (Last 30 days):

Date, Location, SKU, Qty_Sold

PURCHASE ORDERS (Last 30 days):

Date, Location, SKU, Qty_Ordered, VendorDon’t overthink it—CSV dumps are fine.

Step 2: Drop This Prompt in AI

Claude Opus 4.1, ChatGPT-5, Gemini 2.5 Pro… pick your fighter.

Analyze inter-branch transfer patterns and inventory imbalances:

FIND THE PROBLEMS:

1. Hot Potatoes: SKUs transferred >3 times between locations

2. Blind Spots: Items ordered externally while available internally

3. Imbalances: Locations with >60 days supply vs <14 days supply

4. Money Pits: Transfers that cost more than the inventory value

CALCULATE THE WASTE:

- Total unnecessary transfer costs

- Value of duplicate safety stock

- Lost sales from poor inventory placement

RECOMMEND FIXES:

1. Items to consolidate to single locations

2. Weekly transfer schedule to prevent emergencies

3. Rebalancing moves needed TODAY (from overstocked to understocked)

4. Top 10 quick wins under $10K

Output a simple action plan with expected savings.No fancy data? Start with even a basic spreadsheet of "what we moved between locations last month" and "what's sitting where right now." AI can work with that.

🎯 Real Companies, Real Wins

Auto Parts Distributor (5 branches):

35% fewer transfers

$180K/year saved on freight

$400K duplicate stock freed

Industrial Supply Co. (3 warehouses):

AI-predicted milk runs = $8K/month saved

Emergency transfers slashed 78%

Building Materials Dealer (4 branches):

Found $300K in “hidden” inventory

External orders cut in half

Fill rates up 12%—no extra stock added

🚀 Bottom Line

Every Monday morning, while you’re sipping coffee, your branches are sabotaging each other:

Chicago buys what Cleveland already owns

Dallas ships what Houston should keep

Everyone hoards stock like doomsday preppers

AI ends the chaos tonight.

Tomorrow, you’ve got a clean plan—and real dollars back in your pocket.

Every day you wait, your team spends 15 minutes on tasks AI does in 15 seconds.

One short call is all it takes to:

Break down your current workflow

Spot the bottlenecks draining time and profit

Show you how to flip the switch to instant processing

👉 Don’t let another week slip. Book your free Strategy Session now.